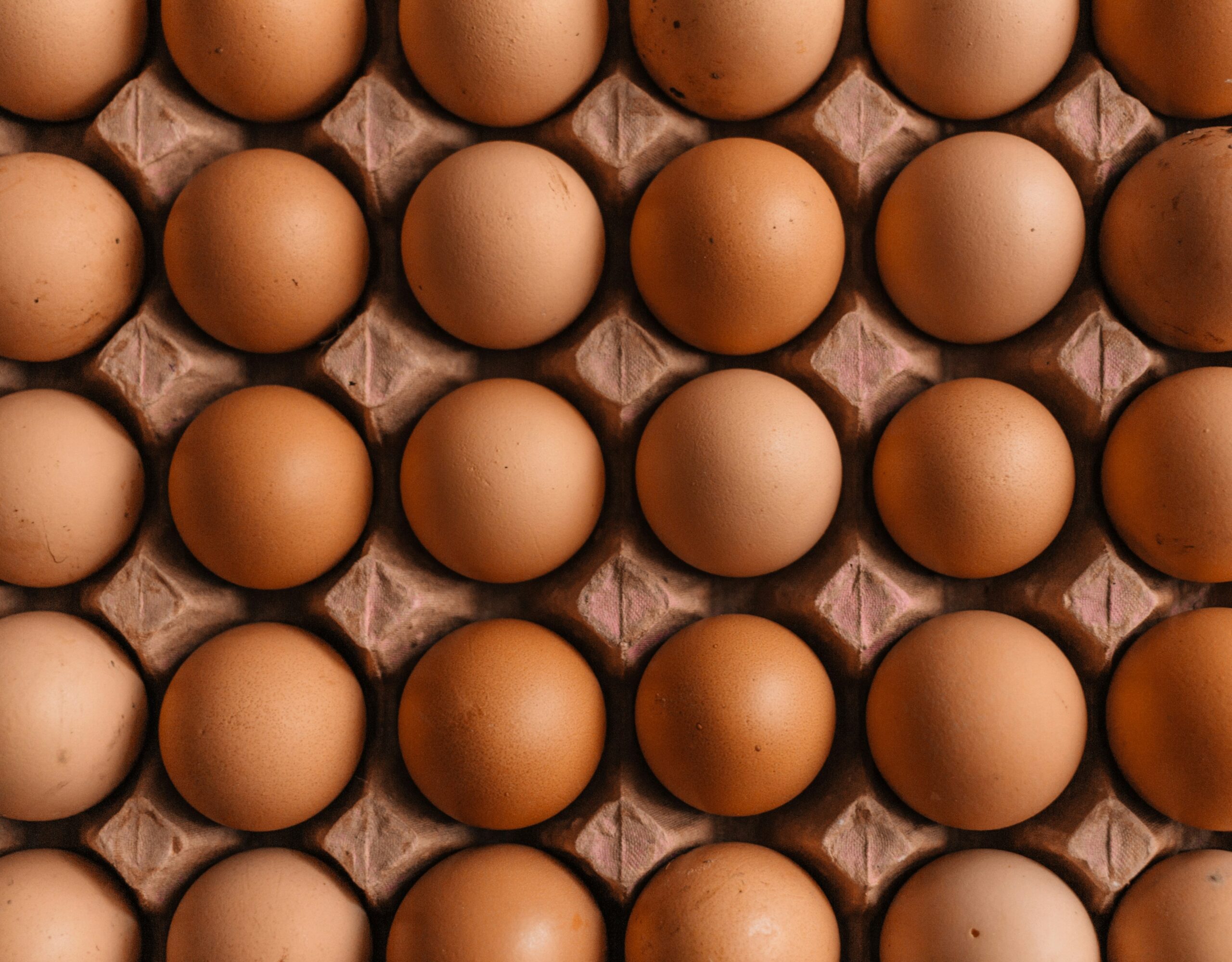

Your one-stop shop for all things eggs starts with Moba.

No matter the size of your operation, Moba offers a comprehensive range of equipment to streamline your workflow, from packing and grading to efficient farmpacking solutions. With over 77 years of experience, Moba is the trusted name in egg processing – and we’re proud to be their partner in New Zealand.

Looking for inspiration? While we gather local Kiwi success stories, head over to Moba to discover how Moba has helped egg producers worldwide. Explore case studies from the Welsh valleys to the Philippines, and see how Moba’s expertise, equipment and local knowledge have helped tackled diverse challenges across the globe.

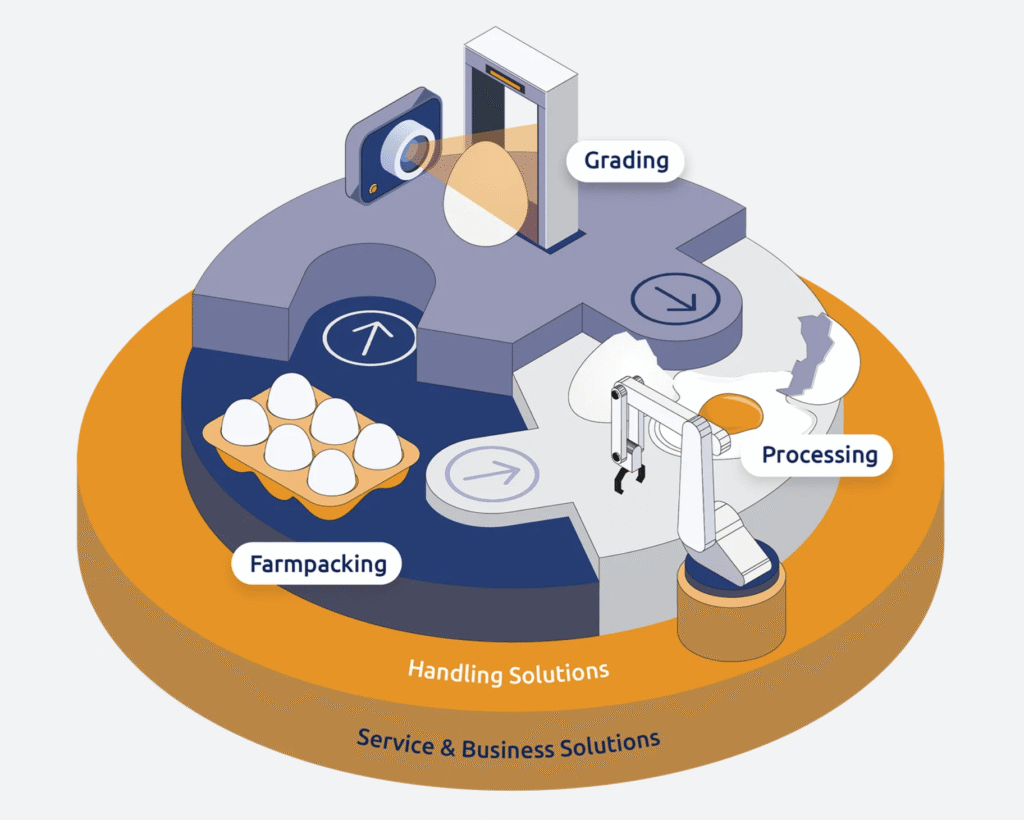

Dive into Egg Processing

Choosing the Perfect Egg Grading System: With our extensive range of egg grading and packing equipment, we offer global solutions that meet all your needs. Finding the right egg grading or packing systems requires expert advice. We offer personalized customer service to ensure that the solution you purchase is a perfect fit for your business. A new system is a significant investment, but it should be a valuable asset to your workflow and throughput.

Choosing the Perfect Egg Grading System: With our extensive range of egg grading and packing equipment, we offer global solutions that meet all your needs. Finding the right egg grading or packing systems requires expert advice. We offer personalized customer service to ensure that the solution you purchase is a perfect fit for your business. A new system is a significant investment, but it should be a valuable asset to your workflow and throughput.

Moba’s Advanced Egg Processing Technologies: Moba offers complete solutions for new and existing plants, including liquid and egg powder pasteurizing lines. Our egg processing systems ensure efficient, high-quality with advanced technologies and reliable performance.

Enhance Efficiency with Moba’s Advanced Egg Packaging Technologies: At Moba, we understand that efficiency and reliability are crucial for your packaging processes. As a global leader in the production of egg packaging machines, we offer innovative and high-quality solutions that meet the highest industry standards.

Tray Handling: Eggs are transported in trays there trays need to be handled in different functional areas of an egg packing and processing plant. Moba has developed a wide range of solutions to automate those tasks. Examples are tray depalletisers, tray stackers and top lidders.

Case Packing: One of the primary processes of a packing station is to pack consumer packs into cases or crates. Moba has fully automated case packing solutions for the widest range of packaging types in the industry.

Case Palletising: Moba case palletising allows you to reduce heavy work and operational costs. Moba offers a wide range of different configurations and capacities up to 1000 cph (half-case). We also provide further automation for the logistics before and after the case palletiser. Examples are pallet stretch wrapper, transfer cars, case sorting unit and pallet labellers.

Transport Systems: Transport systems are the linking pin between the different functional areas of the packing station. And they are the “fil rouge” of Moba systems: conveyors are a crucial part of automation, as their usability is strongly related to the total system integration. An example is Moba’s Contiflow system, which offers optimum flexibility and can merge, transport, sort and buffer a range of consumer packs, as well as pulp trays. With the Contiflow system, you can transfer up to 65,000 eggs/hour per level, depending on the pack size.

Every Egg Processing Operation is Unique

For specific examples and guidance tailored to New Zealand, feel free to contact us. We understand that each business has its own needs, and we’re here to answer your questions.

Ready to Get Started?

Considering entering the egg industry? Moba offers low-volume egg graders – the perfect starting point for smaller operations.

Looking to scale up? We can help you find equipment with increased capacity and features, including tray washing, stacking, and farmpacking solutions. Give us a call today and let’s discuss.

Feel free to get in touch, and we can discuss the solutions we offer and how they can assist. We have a range of documentation, including detailed technical specifications, that we are happy to share and discuss.

You can also check out Moba’s YouTube channel.

Video: Egg Crack Detection With the Moba Vision Shell Inspector

The revolutionary Vision Shell Inspector is a groundbreaking system where cracks in the eggs are detected in a contactless way. No need for maintenance and cleaning time is significantly reduced. Egg touching parts are replaced with cameras and artificial intelligence that will help you become more independent of scarce labour, increase food safety and optimise the added value per egg. (Video length: 6 min)