Baking Equipment: Sieving and Filtration Equipment Designed for Bakeries

Available in NZ, these bakery focused hygienic sieving and filtration solutions ensure consistent quality, reduce waste, and boost productivity for bakeries. From small artisan bakeries to large-scale manufacturers, we tailor solutions to your needs.

Key Equipment

Grading Sieves

High-performance sieves to accurately separate different particle sizes. Our units are designed to increase your productivity, protect your operators and minimise maintenance costs. Unique and patented design features make our equipment very different to the traditional units you may be using now. We also offer a range of options and can customise our products to suit your application and installation perfectly.

Russell Finex Separator™

Check Screeners Improve Your Product Quality

Industrial check screening equipment, also known as safety screeners or quality control sieves, protect the quality of your powder or liquid products by removing oversize contamination. Our units are designed to increase your productivity, protect your operators and minimise maintenance costs. They are also very small and can be fitted into existing production lines. We offer a range of options to suit your screening requirements and can customise our products to suit your application and installation perfectly.

Russell Finex Compact Sieve

High-Capacity Liquid-Solid Separation Equipment

Our range of liquid-solid separation equipment continuously removes solid materials from your liquid slurries, helping you recover or reduce waste. Our units are designed to increase your productivity, protect your operators and minimise maintenance costs. We offer a range of options and can customise our products to suit your application and installation perfectly.

Centrifugal Separators

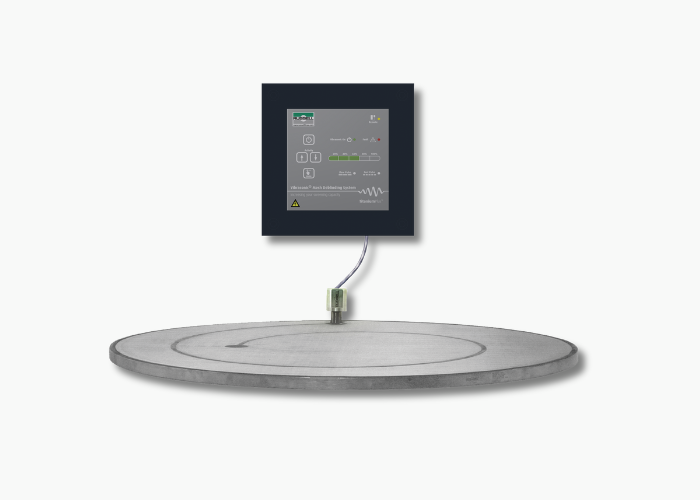

Ultrasonic Mesh Deblinding Systems

Improve your product quality even further. The Russell Vibrasonic® Deblinding System enables sieving on finer meshes (down to 20 microns) without any blocking or blinding of the apertures. This allows you to improve your final product quality and significantly increase your screening capacity. It also increases the life of your mesh screens as they no longer need to be removed and cleaned mechanically by your operators. Our ultrasonic systems can be fitted to new and existing vibrating sieves and screeners. Russell Finex invented the use of ultrasonics with sieves and is the only company to manufacture both sieving and ultrasonic equipment. This allows us to fully optimise their integration to give you the best solution.

Russell Vibrasonic® Deblinding System

Why Leading Bakeries Choose Russell Finex

+ Food-safe design: All equipment is built to meet the highest hygiene standards, including FDA, EN1935/2004 and 3-A compliance.

+ Reduce downtime: Easy-clean designs and tool-free disassembly keep your production line moving.

+ Improve product quality: Remove contaminants and oversize particles from flour, sugar, cocoa, and other ingredients.

+ Custom solutions: From small artisan bakeries to large-scale manufacturers, we tailor solutions to your needs.

Local Expertise and Support

With Advanced Packaging Systems as your exclusive agent in New Zealand, you have a local partner dedicated to providing unmatched service, support, and expertise. We understand your unique needs and challenges and are committed to delivering tailored solutions.

For detailed specifications and downloads for each solution, contact us now, and we’ll be happy to chat about your requirements and our solutions. Contact Us.