Clean-in-place solutions and benefits for New Zealand processing and packaging

Clean-in-place (CIP) approaches are central to processing and packaging, ensuring both product safety and operational efficiency. These systems enable the automated cleaning of machinery and surfaces, without extensive disassembly, using controlled rinsing, washing, and sanitising cycles tailored to each production environment.

Integrating advanced CIP systems has become a benchmark for industry-leading brands, driving improvements in hygiene, traceability, and cost-effectiveness.

Key Benefits of CIP

+ Minimises human errors by automating cleaning tasks, ensuring the correct solution strength and complete rinsing every cycle.

+ Improves health and safety by limiting direct employee contact with cleaning chemicals, reducing accident and exposure risks.

+ Boosts operational efficiency by significantly decreasing cleaning downtime and freeing up staff for other production tasks.

+ Enhances product quality and consistency by ensuring thorough, repeatable cleaning, reducing the chances of contamination.

+ Conserves resources such as water, chemicals, and energy through precise, controlled, and repeatable cleaning actions built into the automated system.

Russell Finex Grading Sieve

Ensuring Food Safety and Compliance

In any food-centric facility, stringent hygiene standards are foundational to preventing contamination risks. CIP reduces human error through its consistent and reproducible cycles, lowering the odds of microbial outbreaks and recalls.

Brands like Silverson Machines and Russell Finex offer mixers, sieves, and filtration equipment with hygienic, easy-to-clean designs meeting international safety standards. Their technologies and design include features for rapid, thorough clean-in-place cycles.

Reducing Downtime and Labour Costs

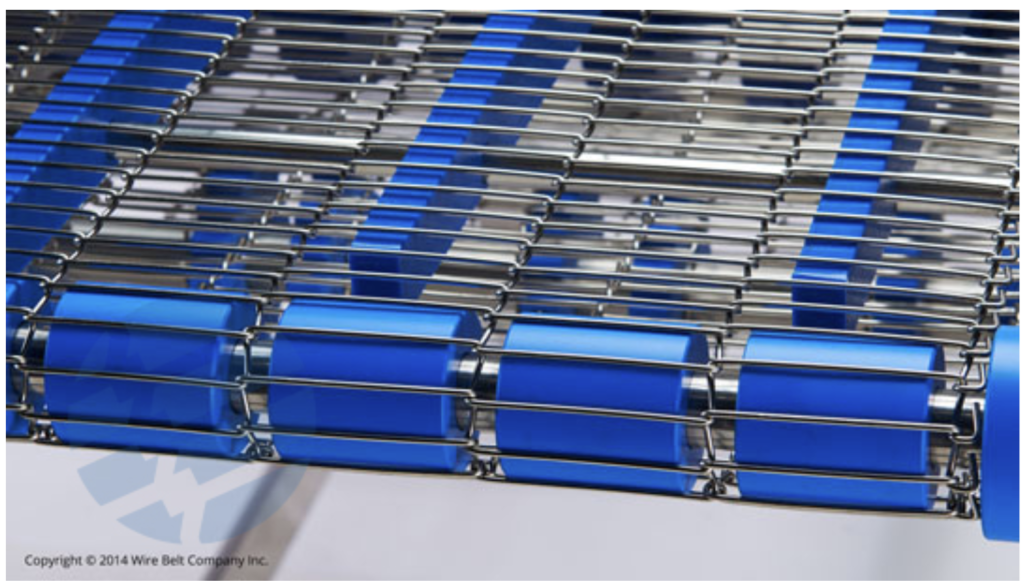

Manual cleaning of production lines traditionally demanded lengthy shutdowns and significant labour resources, slowing productivity and increasing overheads. CIP enables manufacturers to clean machines, from mixers to conveyor belts, swiftly and efficiently, drastically cutting downtime. The Wire Belt Company, a leader in conveyor belt technology, as well as Ashworth, renowned for its stainless steel spiral freezer conveyor belts, designs equipment for seamless integration with CIP systems. These belts are often engineered with open constructions and nonporous surfaces, allowing for high-pressure washdowns and chemical rinses.

Harro Höfliger Modu-C LS Capsule Filler

Enhancing Product Quality Through Consistency

Precise cleaning techniques facilitated by CIP also play a vital role in ensuring batch-to-batch consistency, a key market differentiator for premium producers. Dinnissen, known for its powder handling and blending equipment, incorporates automated cleaning cycles as standard for its machinery. This reliability reduces cross-contamination between ingredients such as allergens or flavourings.

Examples of CIP-Ready Equipment from APS Partners

- Silverson Machines: Specialise in high shear mixers designed for rapid clean-in-place, especially where sticky or viscous products pose cleaning challenges.

- Ashworth & Wire Belt Company: Conveyors built for easy access and CIP integration, ensuring sanitation between product runs without lengthy downtime.

- Russell Finex: Sieves and separators equipped with self-cleaning filtration options to streamline production and meet rigorous hygiene standards.

- Dinnissen & Hanningfield: Powder handling systems provide cleaning processes that are critical for allergen management and pharmaceutical-grade cleanliness.

- VH Vertical Packaging & Zalkin: Vertical form fill seal and capping technologies engineered for automated cleaning and enhanced traceability in packaging operations.

Wirebelt Flat Flex

Local Expertise and Support

With Advanced Packaging Systems as your exclusive agent in New Zealand, you have a local partner dedicated to providing unmatched service, support, and expertise. We understand your unique needs and challenges and are committed to delivering tailored solutions.

For detailed specifications and downloads for each solution, contact us now, and we’ll be happy to chat about your requirements and our solutions. Contact Us.