Waste as a Process Issue

For high‑volume bakeries and food manufacturers, waste is often a by‑product of tight specifications and high throughput: any crumpets, English muffins, wraps or other baked goods outside target weight, diameter, colour or thickness are pulled from the line.

On many sites, the problem is not that waste cannot be recovered, but that existing mixing and handling equipment cannot reliably convert rejected product into a consistent, pumpable, reusable ingredient. Conventional agitators struggle to break down baked goods or confectionery into fine, uniform particles at realistic cycle times, so rework becomes slow, labour-intensive and risk prone.

Bakery Example: Rejects to Ingredient

A flagship bakery case shows the impact when reclamation is engineered correctly. A large baked goods manufacturer running 24/7 was rejecting around 2 tonnes of crumpets per day because strict quality checks removed any product outside spec for size, shape, colour, or thickness. Case Study: How Silverson helped a bakery company reduce waste and save millions of pounds.

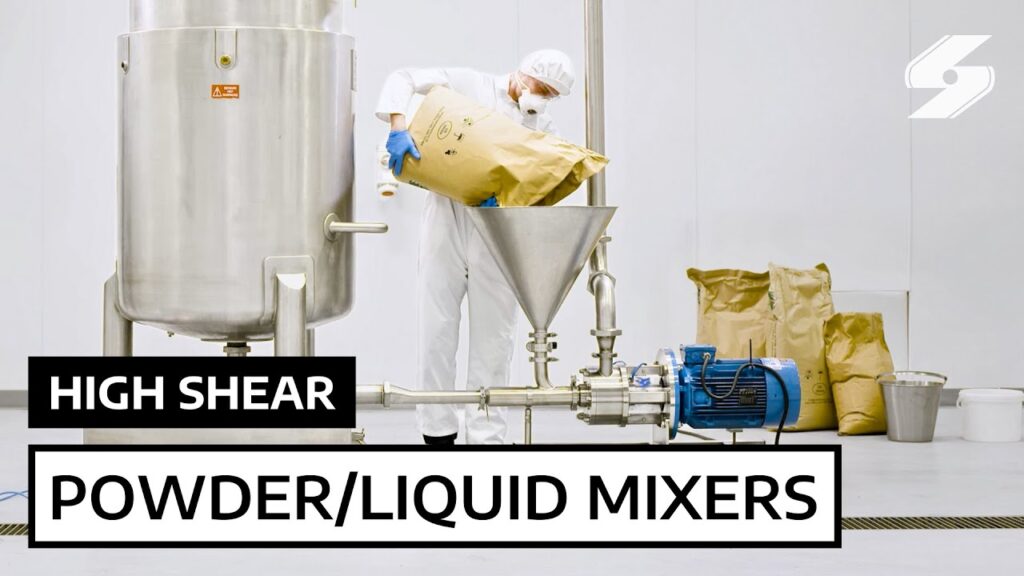

Why High Shear Reclamation Works

High shear reclamation succeeds because it fixes three failure points common to conventional rework systems: energy density in the mixing zone, circulation, and control over final particle size distribution.

- Energy density: A Silverson rotor–stator workhead generates high tip speeds with tight clearances, creating intense shear and turbulence. This is far more effective at breaking down bakery crumb structure, starch gels or sugar matrices than low-speed impellers, enabling rapid size reduction even for resilient or partially dried products.

- Circulation: Bottom Entry designs position the workhead at the lowest point in the vessel, drawing material from the surface down and expelling it radially, which creates a top‑to‑bottom circulation loop and minimises dead zones. Combined with In‑Line recirculation, every part of the batch passes repeatedly through a high shear region, tightening the particle size distribution.

- Control: Because rotor speed, flow rate and batch volume are known, specific energy input can be correlated to slurry properties such as viscosity, particle size and stability. This allows operating windows where the reclaimed stream is consistent enough to be treated as a standard ingredient in downstream dough or batter systems.

Beyond Bakery: Confectionery and Liquid Foods

The same principles apply well beyond bakery offcuts. In confectionery production, misshapen candies, off-cut jellies or agglomerated products are difficult to rework with standard agitators; high shear reclamation systems disintegrate this material into a liquid or semi-liquid phase from which sugar and other ingredients can be recovered, improving overall yield.

In sauces, dressings and emulsions, high shear mixers recover value from out‑of‑spec product by eliminating lumps and restoring emulsion stability through fine droplet dispersion and uniform distribution of emulsifiers.

Silverson Ultra Hygienic InLine Mixer

Key Equipment for APS Customers

For APS’s New Zealand client base, several Silverson solutions are central to waste reduction and reclamation.

- Bottom Entry Mixers: Installed in the base of a vessel, these units excel at wetting out and disintegrating solids into a liquid carrier, making them the primary workhorse for converting bakery rejects into a coarse slurry with short residence times.

- High Viscosity In‑Line Mixers: Designed for high‑viscosity, fluids and slurries, these units refine the output of a Bottom Entry stage to produce a smooth, agglomerate-free slurry with tightly controlled particle size, ready for dosing into doughs, batters or fillings.

Framing the Investment Case

For senior management and procurement teams, the commercial case for Silverson based reclamation can be framed around four value drivers: waste reduction, raw material savings, capacity and risk.

Direct waste reduction is measurable in tonnes per year diverted from landfill or low‑value outlets, translating into avoided disposal costs and improved ESG metrics. In the bakery example, recovering a significant fraction of 2 tonnes per day of rejects delivered multi‑million‑pound savings.

High shear mixing also shortens rework and batch cycle times, effectively releasing capacity on critical assets and deferring capex on new lines. Finally, a robust reclamation route reduces operational risk from process upsets, new product launches or tighter retailer specifications, because more material can be brought back within saleable parameters instead of written off.

In New Zealand, tightening waste levies and circular‑economy expectations add another lever: investments in high shear reclamation systems supplied and supported locally by APS can be positioned as both cost-saving and strategically important for future-proofing operations and key customer relationships.

Local Support and Expertise – Enquire Now

For detailed specifications and solution options, contact APS now, and we’ll be happy to chat about your requirements and our solutions. Contact APS.