Lowering Energy Consumption in Food Processing and Packaging with APS Partner Solutions

The food processing and packaging industry is at the forefront of innovation, not just in response to rising consumer expectations, but also due to growing regulatory and community pressure to improve sustainability. Nowhere is this more evident than in the drive to reduce energy consumption. As energy costs rise and carbon footprints come under greater scrutiny, advanced equipment and process optimisation have become essential.

Advanced Packaging Systems (APS) stands out as a solutions provider by partnering with worldwide leaders in food processing and packaging machinery. Through a handpicked portfolio of trusted brands APS delivers tangible opportunities to lower energy usage at each stage of food production and packaging.

Zalkin Oppti.Cap MH Rotary Capper

Smart Conveyor and Freezing Solutions: Precision Means Less Waste

Energy-intensive processes such as freezing and material handling are prime targets for efficiency gains. Ashworth, a leader in spiral freezer conveyor belts, enables manufacturers to move products quickly through freezing zones, minimising dwell times and allowing narrower, more targeted temperature control. Highly efficient conveyors reduce friction losses, resulting in lower power consumption. By optimising the interface between system design and product throughput, processors can achieve consistent product quality with less energy input.

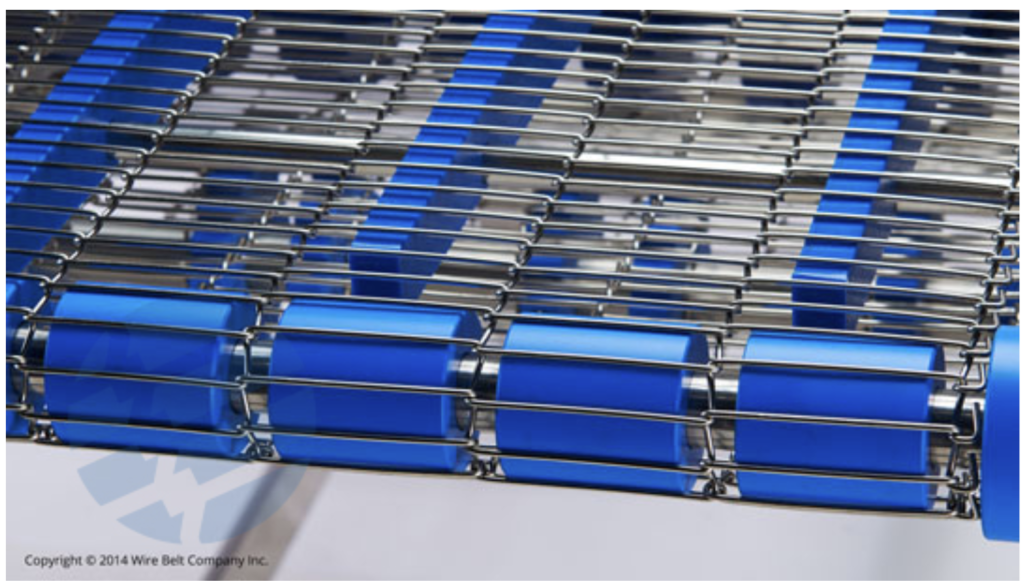

Wire Belt Company, known for its stainless steel conveyor belts, also supports low-friction, high-durability transport solutions that reduce wear and the energy demands of conveyor drives. Efficient transport systems mean fewer start/stop cycles and smoother product flow, further shrinking an energy footprint.

Wirebelt Flat Flex

Powder Handling, Blending, and Hygiene: Less Reprocessing, Lower Overheads

Handling, mixing, and conveying powders require significant energy, especially when inefficiencies result in product loss or the need for repeated processing. Dinnissen offers cutting-edge powder handling and blending solutions engineered for precise dosing and gentle blending. Reduced mixing times and highly efficient drives mean lower energy use per batch, while automated process controls reduce human error and rework.

Hanningfield’s powder milling and containment systems supply closed-loop processing with validation and full documentation, supporting not just product safety but also energy efficiency. Dust containment and gentle yet precise material handling reduce losses and processing times.

Silverson Machines high-shear mixers are designed to maximise mixing efficiency, integrating advanced rotor–stator technology to accelerate processing and cut batch times. Their technology ensures faster, more consistent results, translating directly into fewer operating hours and, therefore, reduced energy bills.

Silverson In-Line Mixer

Efficient Packaging and Labelling Equipment

Packaging is another area ripe for energy savings. UET Cartoning’s compact, flexible machines require less floor space and have been engineered for fast changeovers and minimal idle time, which means equipment only runs when needed, reducing both electricity and maintenance loads. VH Vertical Packaging supplies Vertical Form Fill Seal (VFFS) systems known for fast cycling and reliable automation. Their equipment eliminates bottlenecks, ensuring machines work efficiently without running needlessly between cycles.

Zalkin (bottle capping solutions) design their machines for seamless, high-speed integration into existing lines, minimising downtime – a frequent source of energy waste in older systems. Zalkin’s cap handling systems can switch between cap types with minimal adjustments, reducing machinery idling.

Automation, Data, and Integration

Modern energy efficiency isn’t just about the machinery; it’s also about the intelligence behind it. Many APS partners – from Harro Höfliger (pharmaceutical and medical packaging) to Moba and Meggson (egg processing solutions) – offer machines equipped with digital integration and process analytics. Real-time monitoring and automated adjustments help lines respond dynamically to production demands, ensuring that motors, heaters, or freezers run at their lowest necessary settings.

For example, Moba’s egg grading and processing systems are designed for throughput optimisation, reducing conveyor and sorting run time. Meggson’s egg handling solutions not only streamline egg movement for lower wear but offer palletising and washing systems that operate with short, efficient cycles.

Meggbot TP100

Sieving, Filtration, and Printing: Reducing Processing Load

Russell Finex delivers vibratory sieves, separators, and self-cleaning filter systems that keep production flowing with fewer stops and starts. Continuous processes are inherently more energy-efficient, and Russell Finex equipment is optimised for low power consumption and high uptime.

Nuovo’s egg printing systems use patented print technologies that minimise waste and error, reducing the need for reprinting or excess passes, cutting unnecessary equipment operation.

Sustainable Impact: Efficiency, Reliability, and Local Support

By combining robust, reliable machinery with the latest in automation and process intelligence, APS partner solutions empower New Zealand food processors to sharpen their competitive edge – not just on emissions compliance, but by achieving measurable reductions in electricity and overall resource use.

Energy efficiency is not just about the initial machine; it’s about long-term performance, minimised downtime, and continuous process improvement.

Get in Touch

Like to have an obligation free, informal chat? Don’t hesitate to get in touch.