Dinnissen Sampling System: Versatile Applications Across Industries

Sampling is one of those deceptively simple concepts, you take a small portion of a material and analyse it, yet its role in industry is critical. Whether you’re working with powders in a feed-mill, liquids in a chemical reactor, or granulates in a pharmaceutical line, getting a representative, clean, and consistent sample is essential to quality control, regulatory compliance, process optimisation and safety.

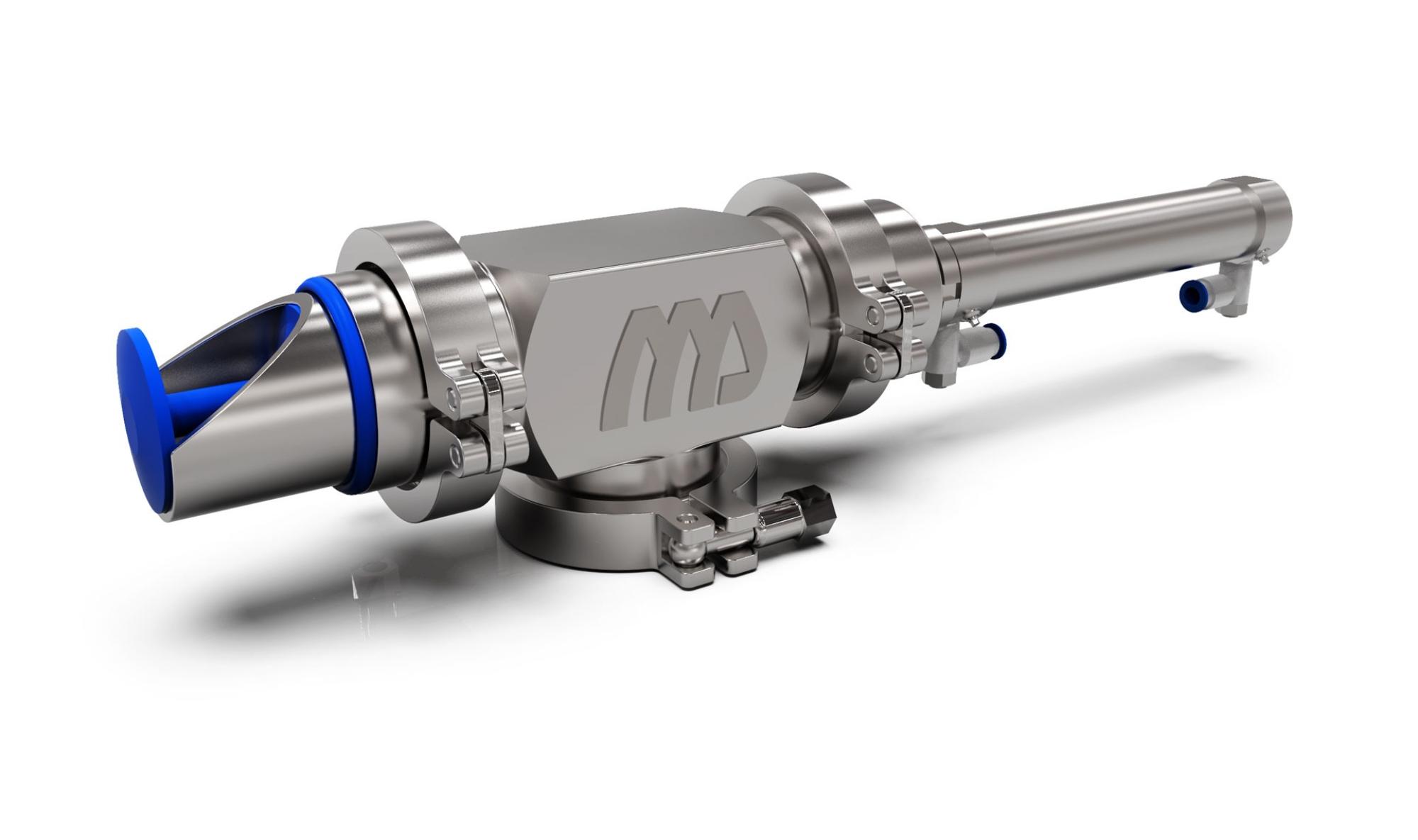

Dinnissen has developed a contamination-free Sampling System for producers in the high-end pharmaceutical and food industries. With this system, samples can be taken fully automatically, without operator intervention. The Sampling System can be used for dry powders, pellets and granulates, both in continuous processes and in batch production.

Key advantages include:

- consistent and accurate samples; easy to apply in silos, transport systems and mixing and packaging installations.

- hygienic design, with minimal seams and gaps, metal detectable interior, quick disassembly for cleaning.

- the system can be used for inbound, intermediate and outbound product flows (e.g., after mixing to check homogeneity, or final product flows to check quality).

Dinnissen Sampling Systems

Key Industries and Use-Cases

Here are several major industries and use-cases illustrating how sampling systems are used in each.

Food & Beverage

Use-cases:

- Sampling raw materials such as powders, granulates, grains, to check moisture content, impurities or foreign matter.

- Sampling intermediate flows (after mixing or conveying) to check homogeneity (essential for fortified foods, premixes).

- Final product sampling to verify specification (e.g., pellet size, density, particle distribution) before packaging.

Pharmaceutical

Use-cases:

- Sampling powders, granules or pellets in drug-product manufacture) to verify content uniformity and particle size.

- Sampling during sterility-sensitive processes (aseptic lines) where risk is high.

- Sampling of final product flows for release testing or quality assurance.

Dairy

Use-cases:

- Sampling of milk powders, dairy granulates (whey, casein, etc) for moisture, fat, and contamination.

- Inline sampling during transfer and mixing steps.

- Final product sampling before packaging.

Chemicals and Minerals

Use-cases:

- Sampling of powders, granules, pellets in mineral/chemical processing (e.g., catalysts, additives, raw materials) for quality, particle size, composition.

- Inline sampling of continuous processes to monitor stability, detect deviation.

- Final product sampling to verify compliance with specifications (e.g., additive concentration, impurity levels).

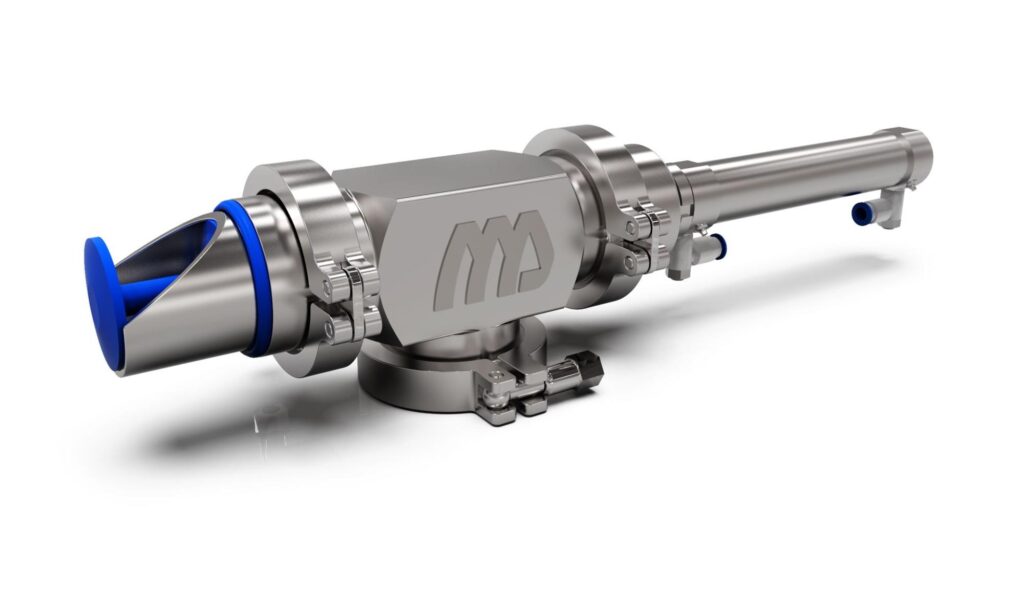

Dinnissen Sampling System Disassembled

Benefits of Automated / Well-Designed Sampling Systems

The benefits of a well-implemented sampling system include:

Representative, consistent sampling

Manual sampling is prone to variation; automated systems help reduce variability and improve reliability.

Hygiene and contamination control

Especially in food, pharma and dairy applications, hygienic design (cleanable, minimal dead-space) matters.

Reduced operator intervention, improved safety

Minimising manual sampling reduces human error, exposure to hazardous materials, and process disruption.

Better process control and traceability

Automated systems allow sampling at set intervals, volumes or weights, integrated into process control systems. The frequency with which samples are taken should be determined by the operator or the control system.

Lower cost and higher throughput efficiency

By catching deviations early and reducing manual labour/time, sampling systems can reduce waste and improve productivity.

Considerations When Designing or Choosing a Sampling System

When implementing or selecting a sampling system, keep in mind:

- Material type: Powders, granulates, pellets vs. liquids require different sampling mechanics.

- Process environment: Continuous vs batch, high throughput, hygienic vs chemical-harsh conditions.

- Cleaning and hygiene: Especially critical in food/pharma; design should allow fast and thorough cleaning.

- Automation level and integration: Ability to interface with control systems, set intervals, and sample weight/volume.

- Representative sampling and variance control: The sampling system must minimise the added variability of sampling itself.

- Regulatory requirements: For example, in pharma or highly regulated chemicals, traceability, documentation and compliance matter.

- Material flow and accessibility: Installing the system on a tube/conveying line means you need mechanical compatibility and safe access.

Sampling systems may not always be top of mind, but they are fundamental to ensuring quality, safety and process efficiency across many industries. The Dinnissen system is a strong exemplar: automatic, hygienic, versatile across powders, pellets, and granulates, and designed for high-end industries.

If you’re involved in production where materials are moving, being mixed, packed or processed, it’s worth evaluating whether your sampling strategy (and equipment) is up to the task. We’re here to help.

Where can I get more information or a quote for Dinnissen powder processing solutions in New Zealand?

Contact us or us on +64 (09) 966 3360.